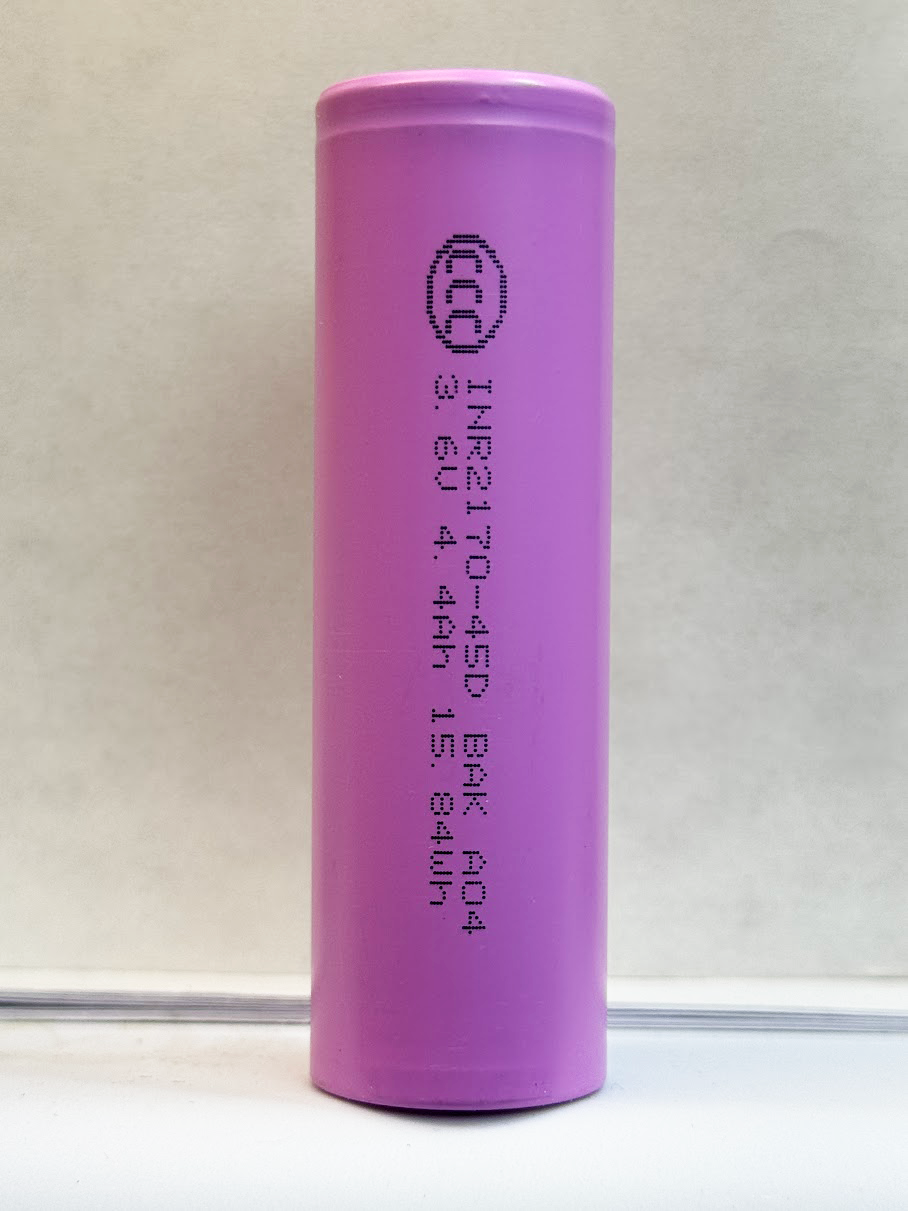

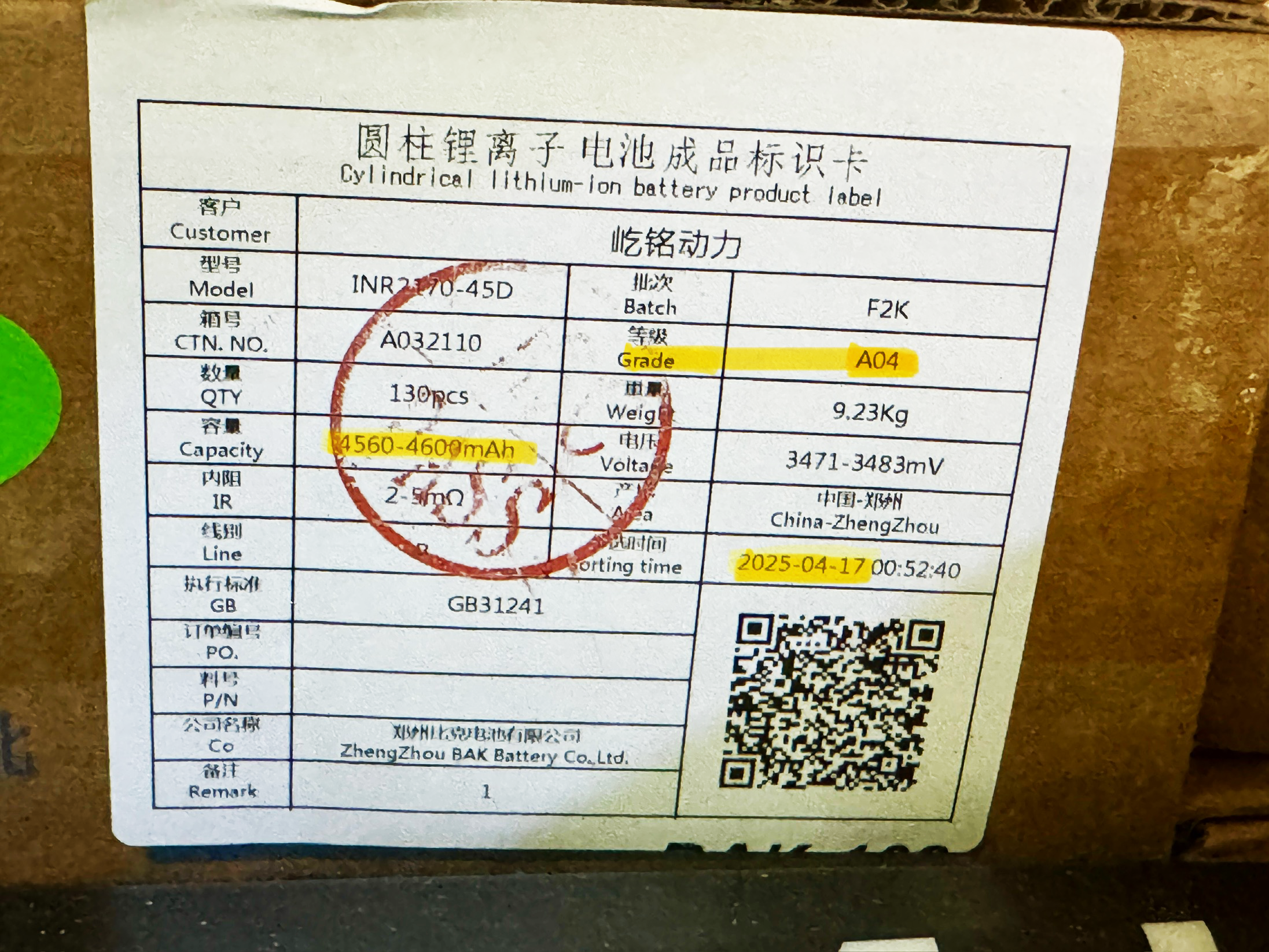

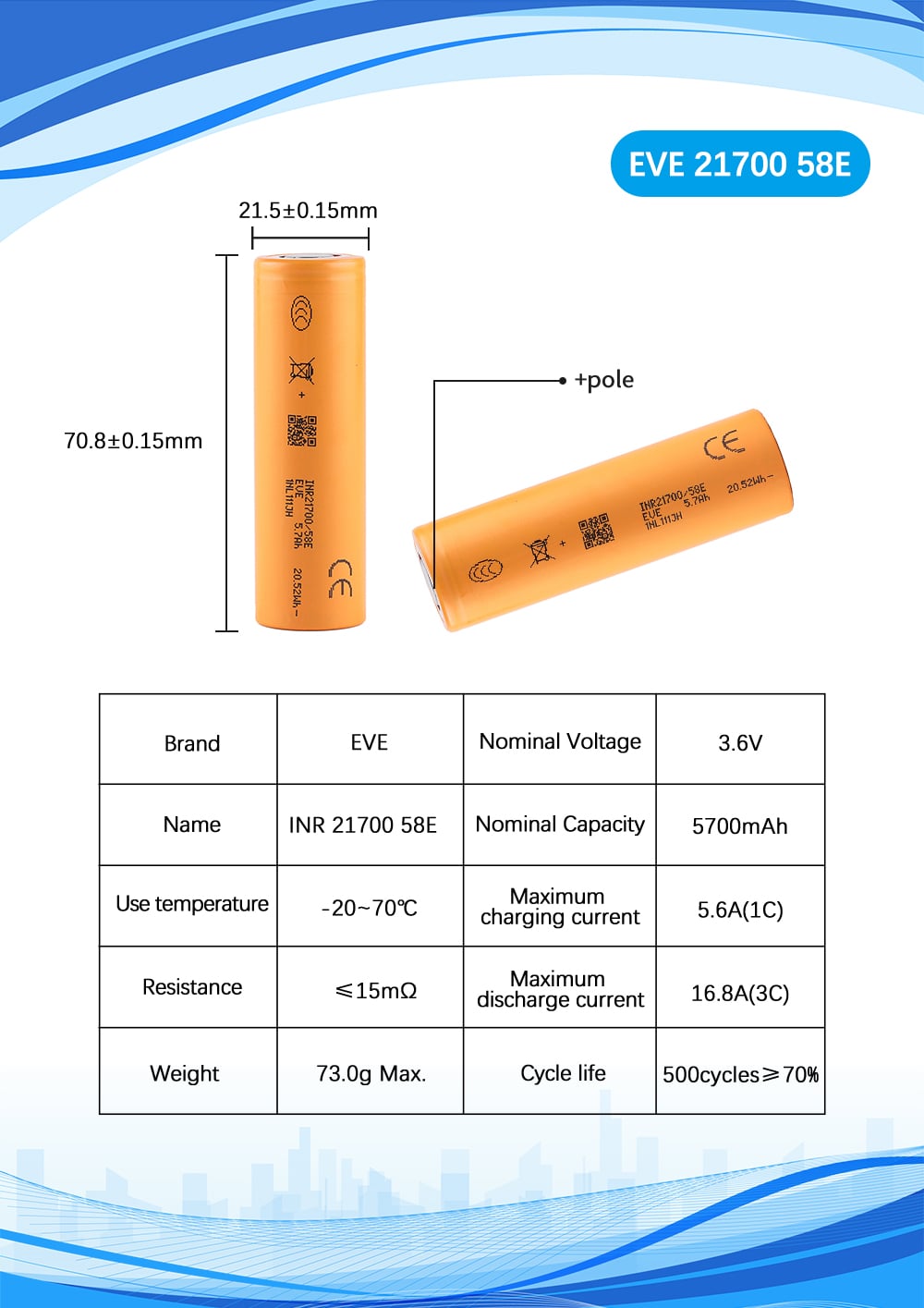

21700 Cells

Save 60%

Sale price$3.95 USD

Regular price$9.99 USD

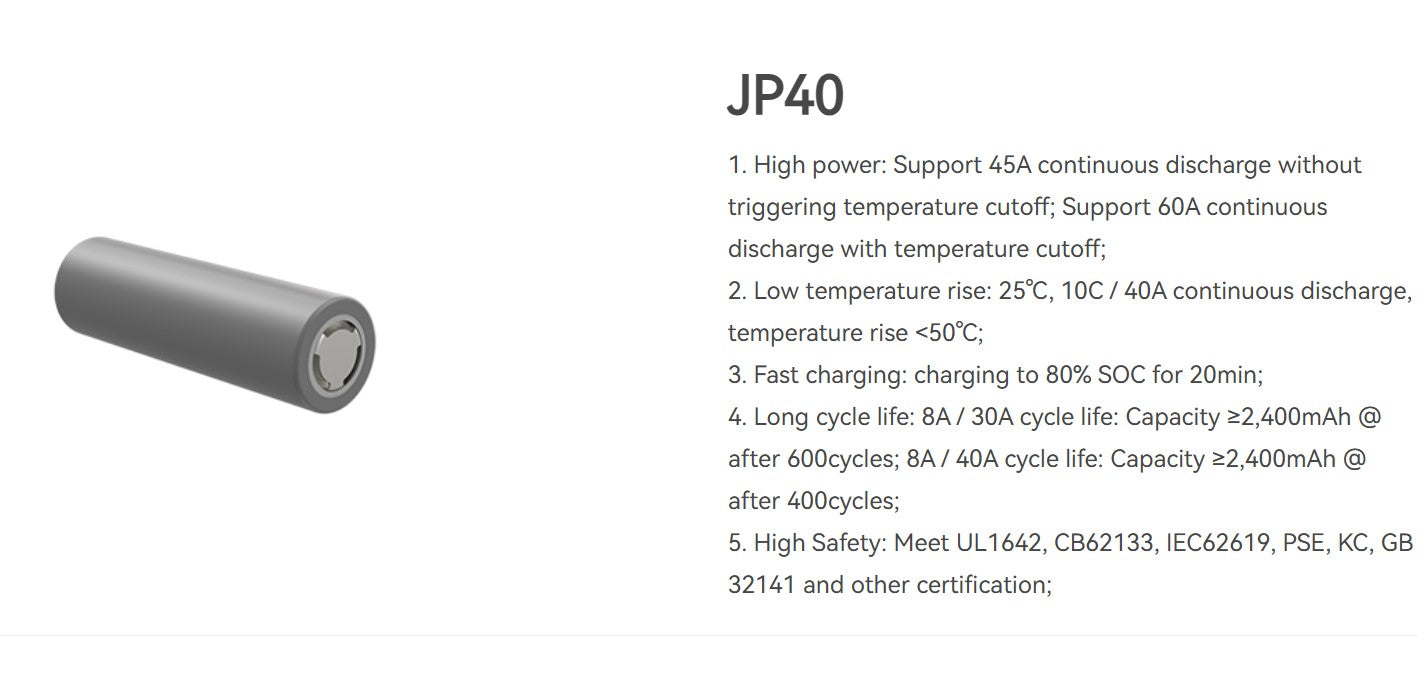

Ampace JP40 "LT Wrap" 21700 4000mah 70A Battery - Tabless CellAmpace

Save 44%

Sale price$6.15 USD

Regular price$10.99 USD

Reliance 21700 RS50 5000mAh 70A Lithium-Ion Battery Tabless Cell - High PerformanceReliance

Save 28%

Sale price$7.15 USD

Regular price$9.99 USD

TENPOWER 50XG 21700 5000 mAh 90A Battery – Tabless CellTENPOWER

Save 43%

Sale price$5.15 USD

Regular price$8.99 USD

LG INR21700 M58T 5800mAh 12.5A High Capacity Battery Cell – Industrial GradeLG

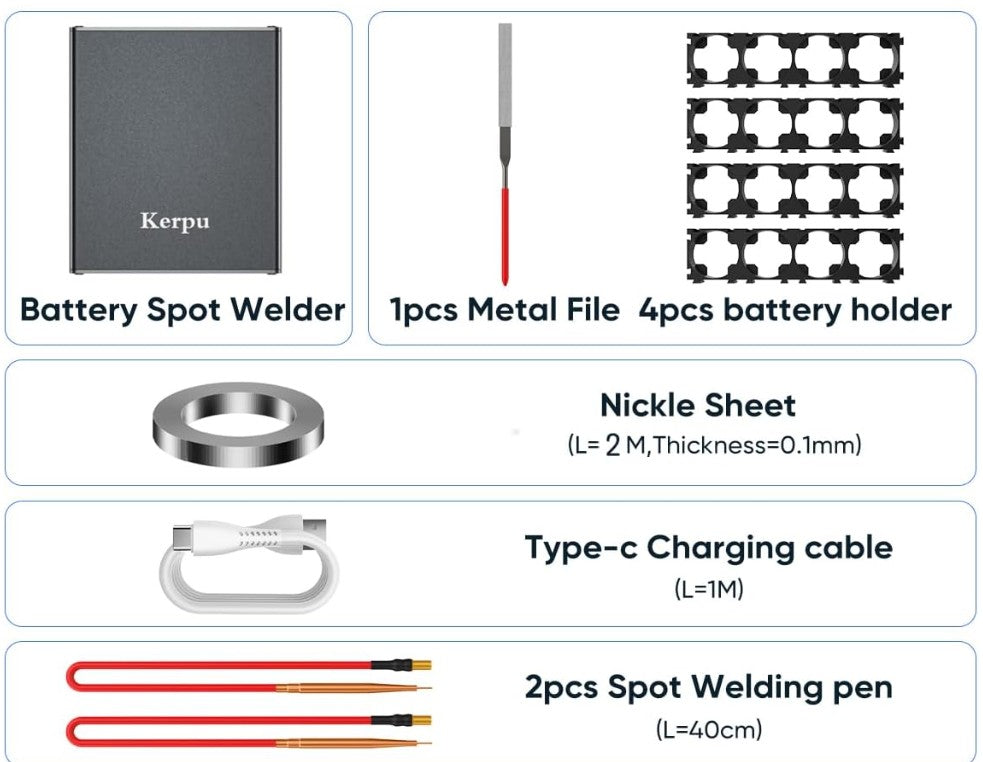

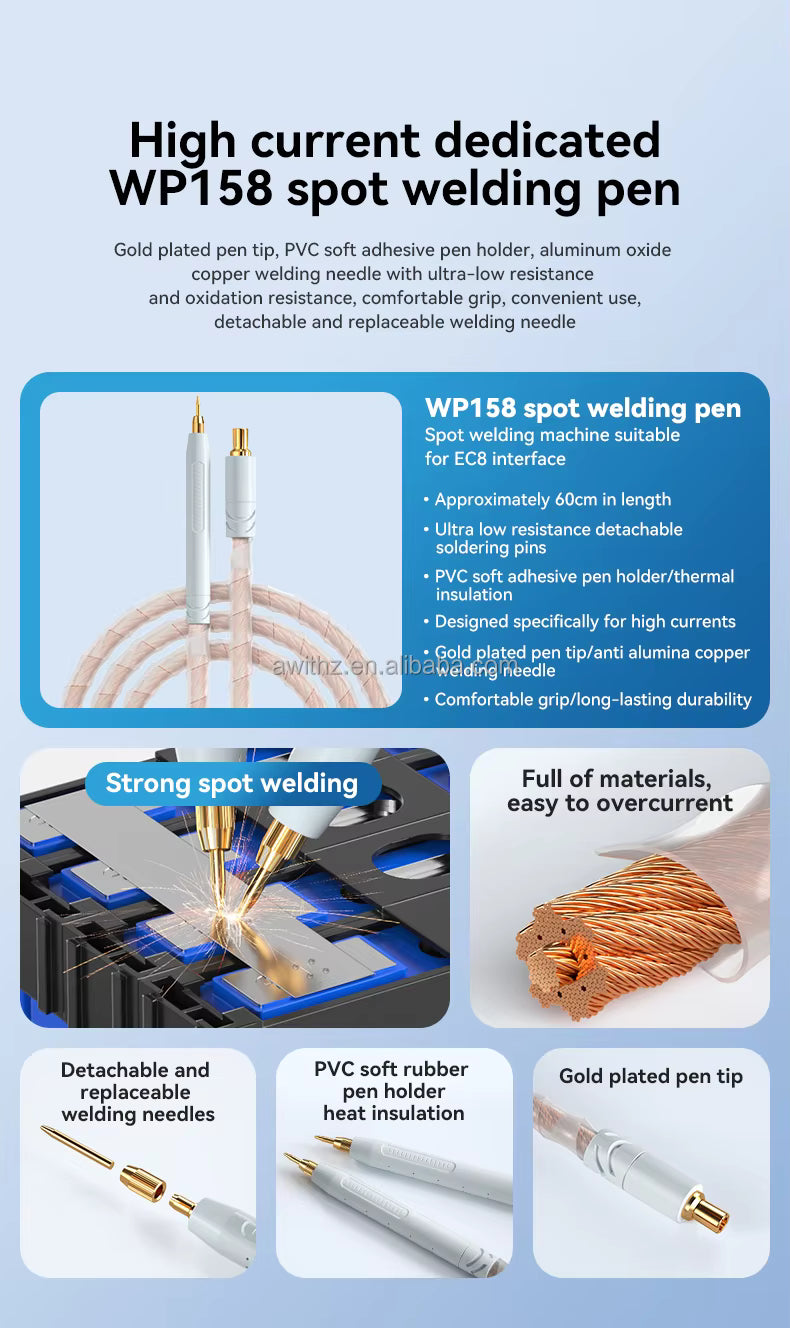

AWithZ Spot Welders

Sale priceFrom $8.95 USD

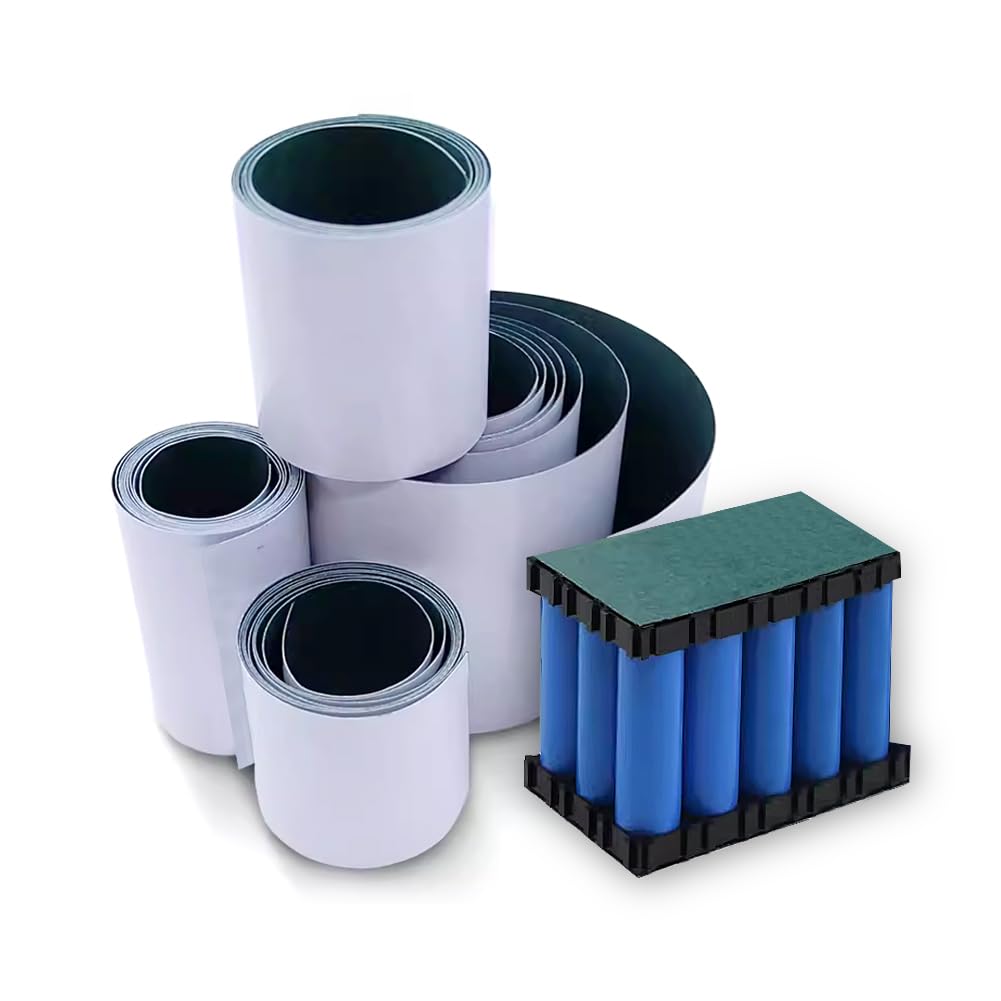

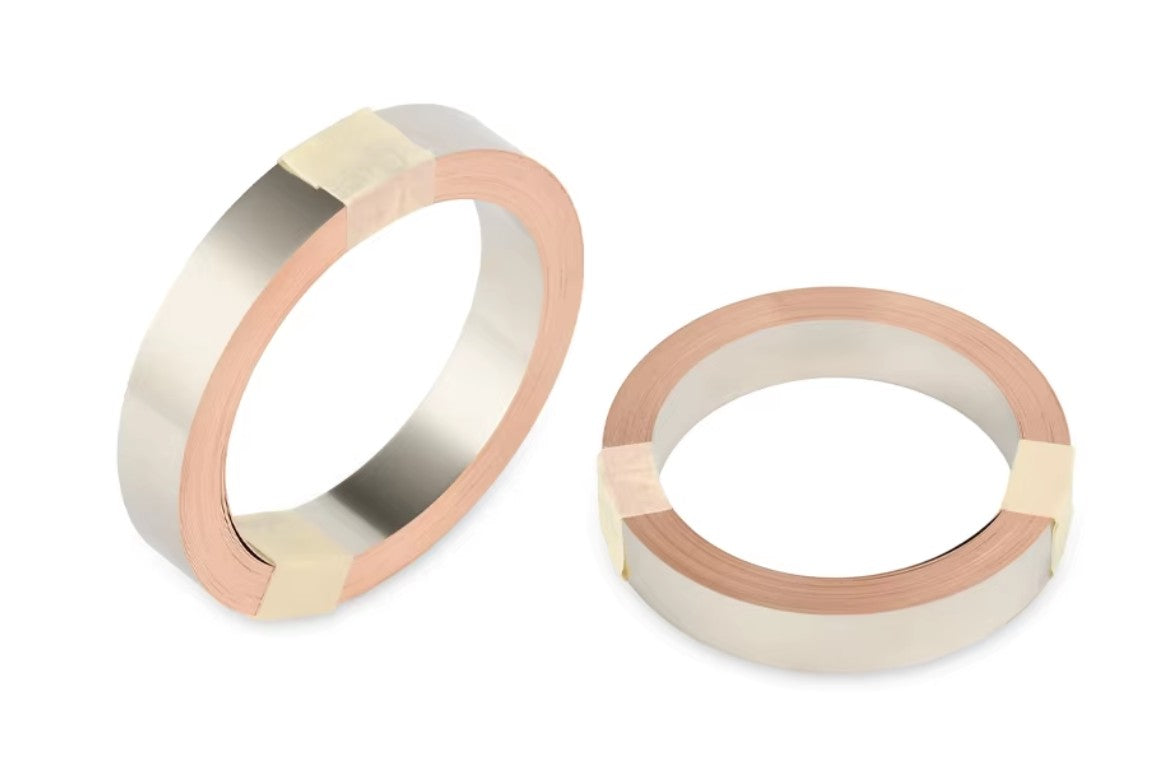

Nickel-Plated Steel Strip for Battery Spot Welding – 5m Roll (Multiple Sizes)DIY500AMP.COM

Sale priceFrom $11.95 USD

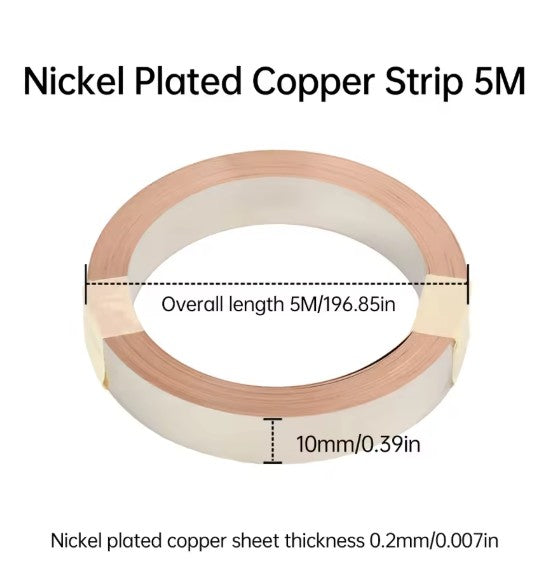

Pure Copper T2 Strip for Battery Spot Welding – 5m Roll (Multiple Sizes)DIY500AMP.COM

Save 14%

Sale price$59.99 USD

Regular price$69.99 USD

AWithZ H5 Mini Spot Welder – 5000 mAh Battery, 0–0.35 mm Welding, TFT DisplayAWithZ